Standard equipment:

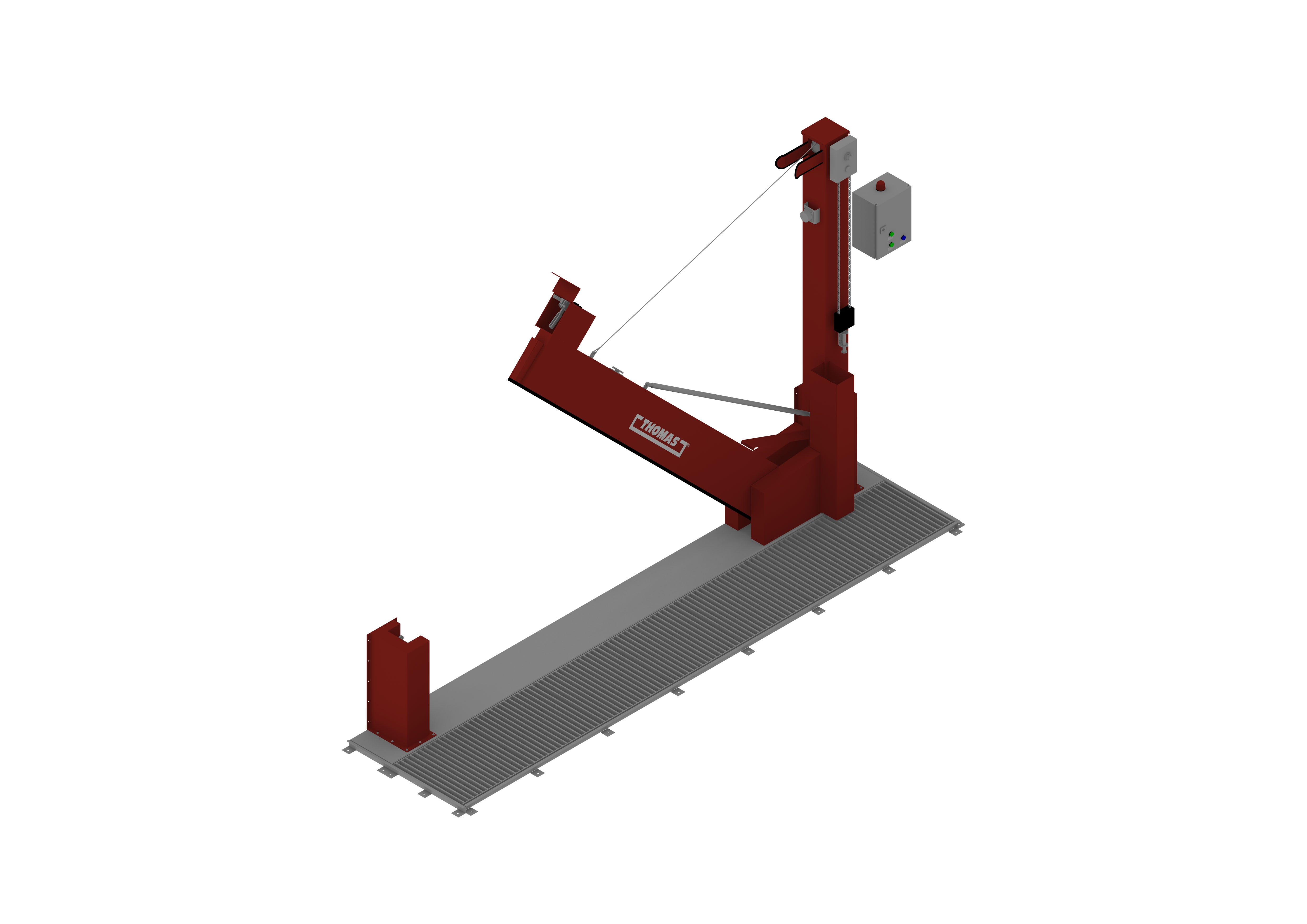

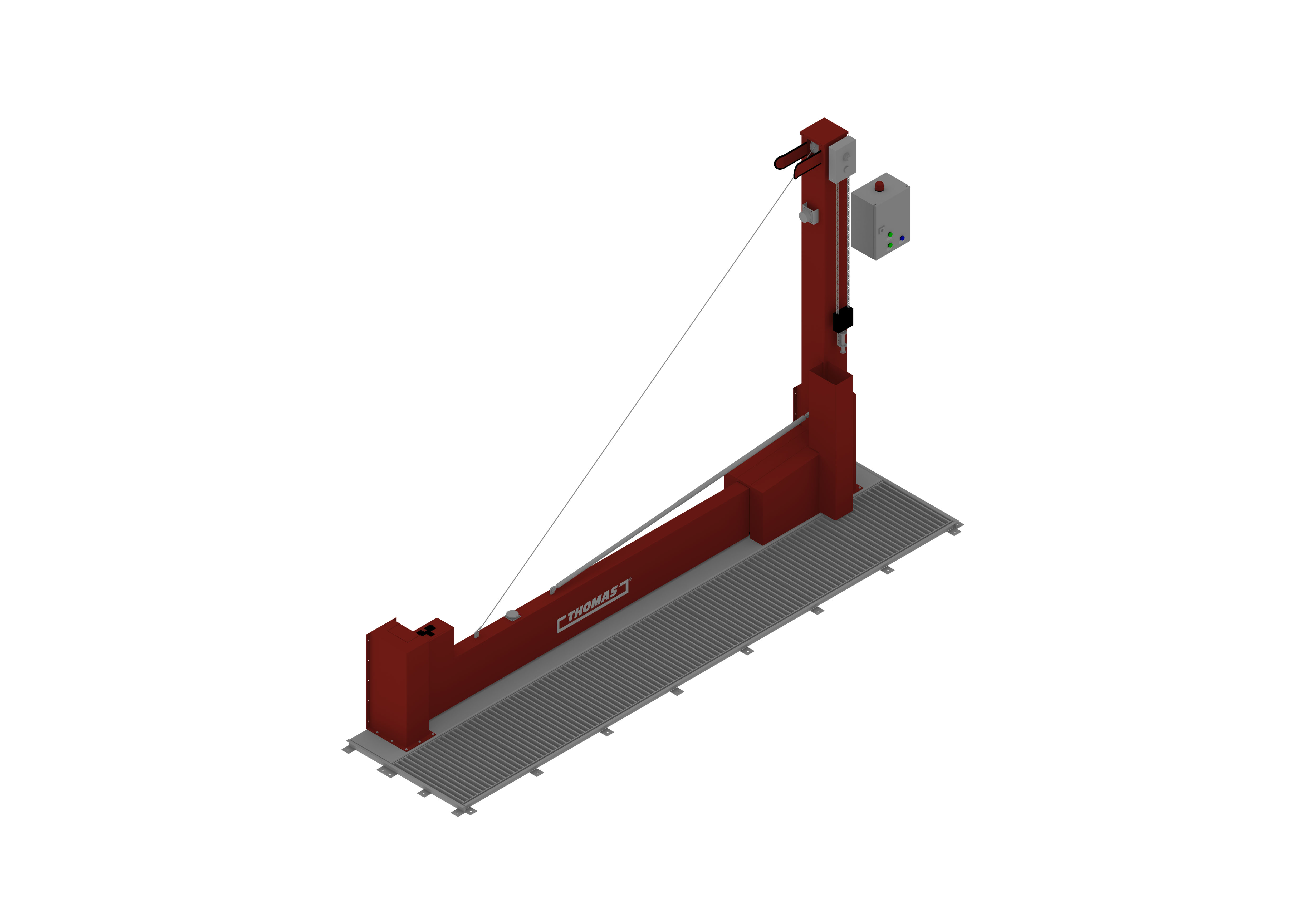

- Full automatically closing process without external energy

- High temperature protection shield on front and back of the barrier

- High chemical resistant PTFE-coated special seals

- Flame protection cover for all special seals on front and back

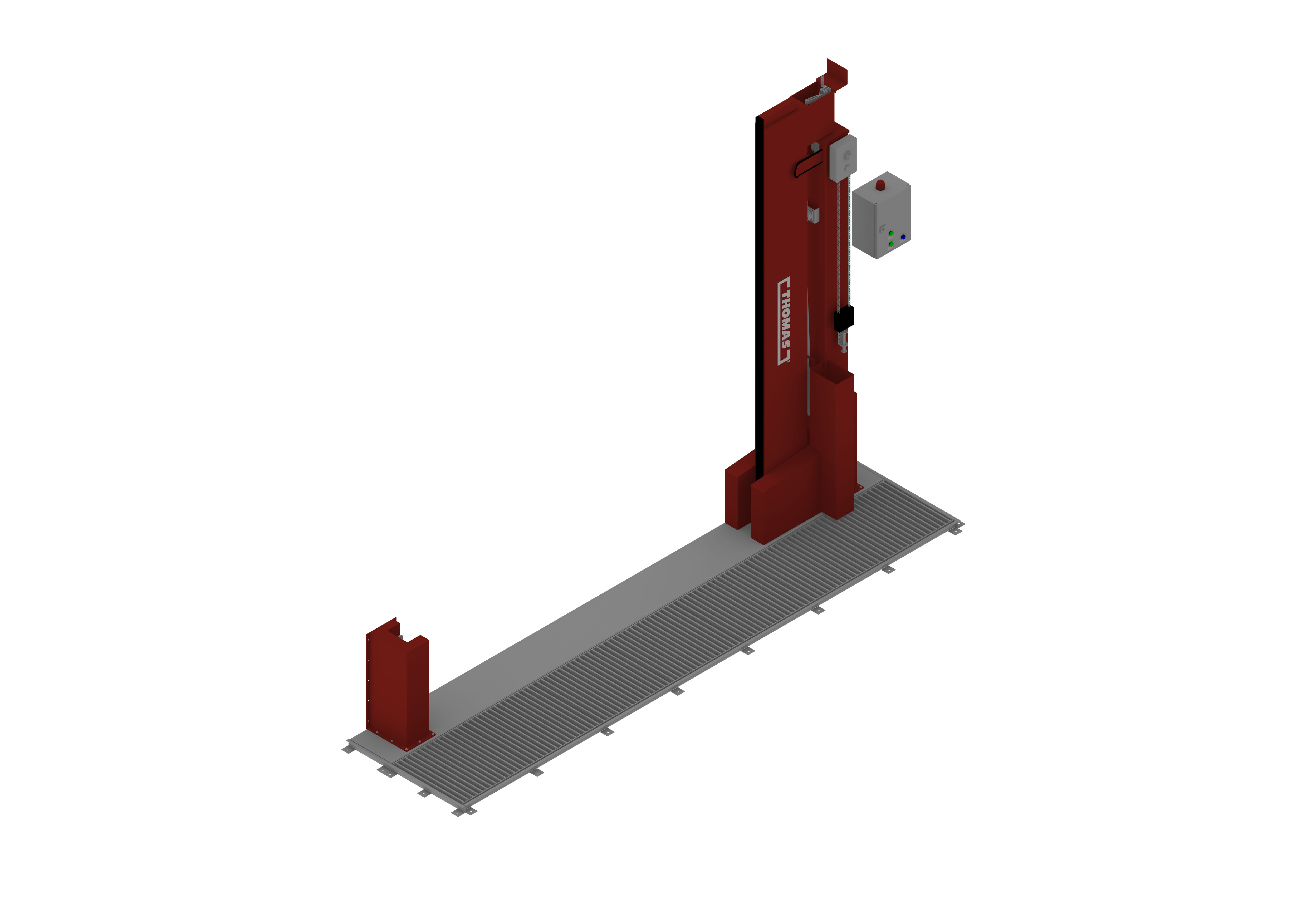

- Channel System and sump steel grating in the floor in front of the barrier with a depth of about 50 mm to collect the leaking substances

- Load class of the channel system: A15 – C 250 for overall load up to 25 tons (wheel loads 7,5/10 tons)

- Automatic closing via liquid probe VS 63

- Automatic closing in case of power blackout

- Manual activation via push button (green)

- Automatic activation via external close signals (optional)

- Reset push button (blue)

- Optical ready indicator (green)

- Optical pre warning and closing signal

- Acoustic pre warning and closing signal

- Cable laying in metal pipes

- Electrical control with SIEMENS-components

- Colour barrier: red RAL 3000

Possible additional options:

- Electrical control with battery backup

- Gas, smoke, thermal, fluid and pressure detectors

- Central control and remote activation

- Ex-proof design of the barrier

- Ex-proof electrical control

- Lock control monitoring

- Impulse tensioner monitoring

- Status signal output

- Galvanized version

- Stainless steel V2A version

- PTFE-coated seals and surfaces

- Higher load class of the channel system: up to A15 – D400 for overall load up to 40 tons (weel load 12,5 tons) or A15 E600 for overall loads up to 60 tons

- Collision protection